A small-scale arsenic and iron removal plant

Practical Action

Maintenance

Regularly clean the outer sides/periphery of the plant and ensure it is free from water

logging

Keep the plant covered with the CI/plastic sheet

Keep the outlet pipes closed

After a 7 days interval flush out the water (opening the outlets) 2 or 3 times and clean the

chambers

After one month or if the performance of the plant is found to be unsatisfactory (test with

the green guava leaves), take out all the media/filter materials separately then clean and

wash with hot water mixed with bleaching powder (10 gm per liter of water), dry in sunlight

and refill.

After one year or if the performance of the plant is found unsatisfactory then all filter/media

materials should be replaced by new materials

Water containing a lot of iron contamination quickly reduces the adsorption and filtration

capacity of the filter/media materials. In this case, the filter materials need to be cleaned

more regularly to keep the plant functional. But if the iron concentration in the raw water is

low, then iron can be added (iron pins/nails could be added with brick chips) to chamber C4

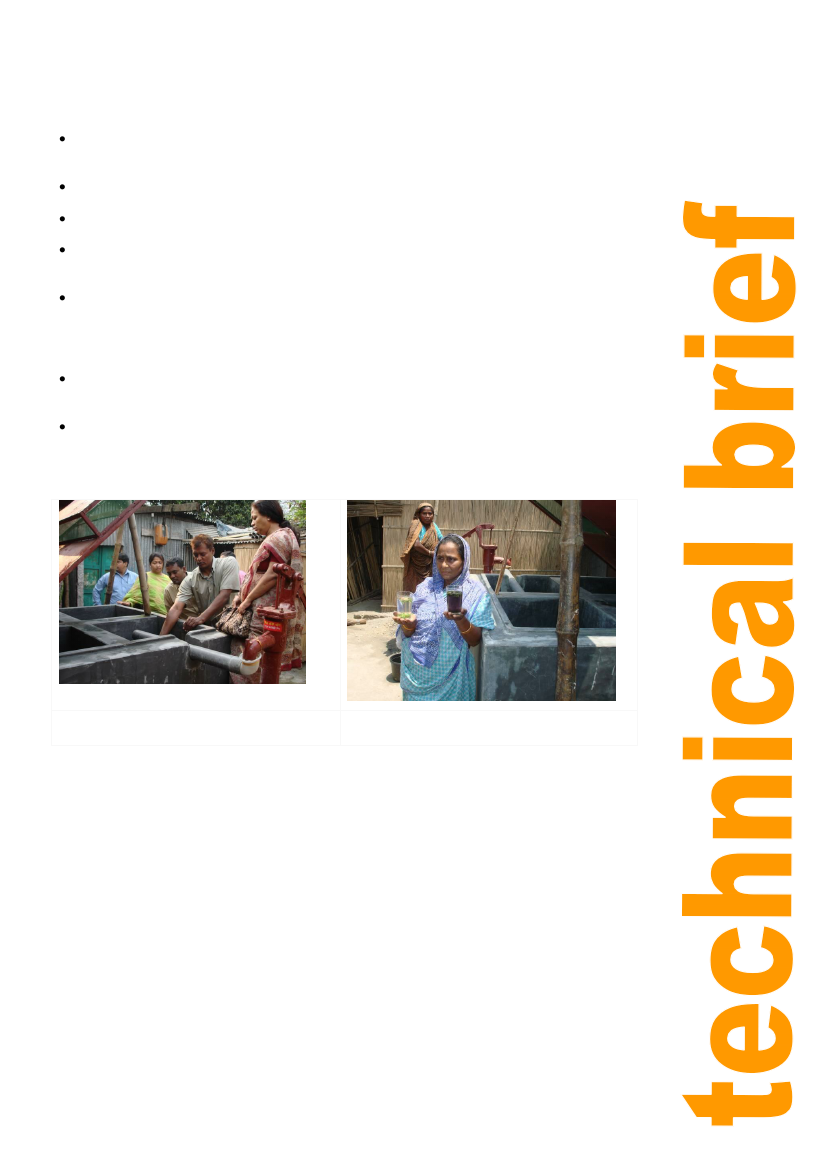

Figure 4: Demonstration of AIRP operation.

Photo: Moin/DRIK.

Figure 5: Arsenic removal monitoring with

guava leaves. Photo: Moin/DRIK.

5